Small-format, fully enclosed waterjet machining center.

Base: 0.65m

Bridge: 1.2 m

Z Axis Travel: 150 mm

Flow Mach 200 Series Waterjet Cutting Machine

Flow Mach 300 Series Waterjet Cutting Machine

Flow Mach 500 Series Waterjet Cutter

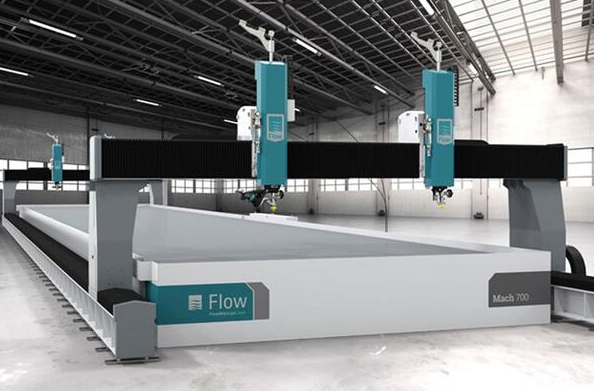

Flow Mach 700 Series Waterjet Cutter

Flow Advanced Solutions Waterjet Cutting

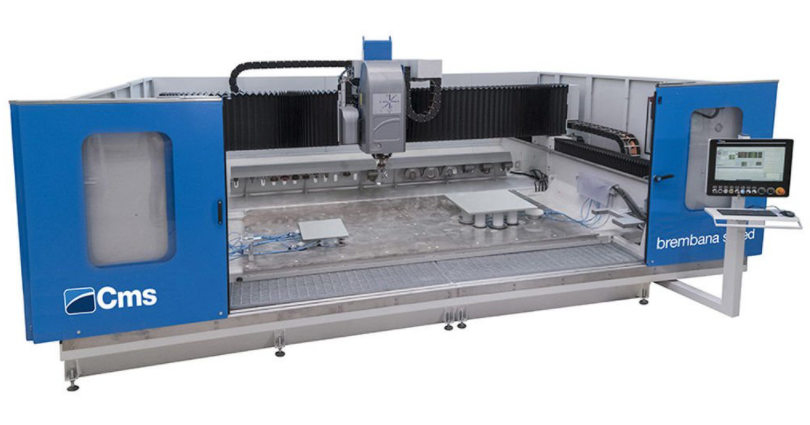

CMS Brembana Speed CNC Machine

CMS Brembana Maxima CNC Machine

CMS Brembana g-rex CNC Machine

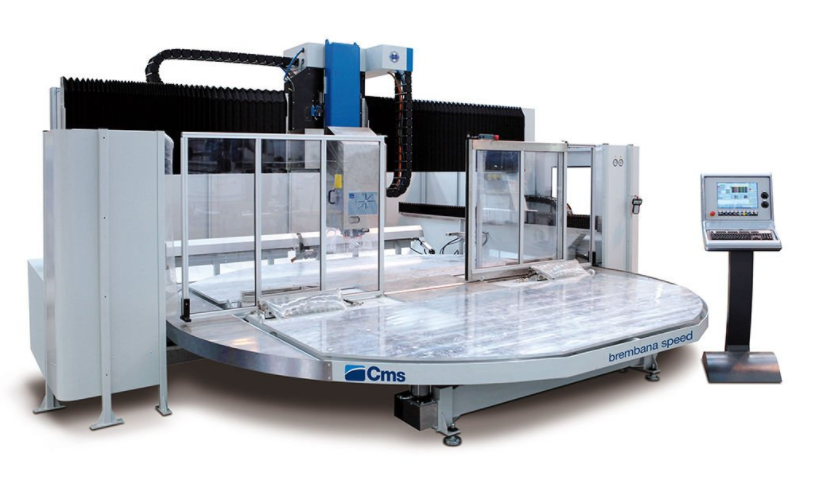

CMS Brembana Speed tr CNC Machine

Fraccaroli & Balzan Waste Water Filtration Plant - SQUARE MODEL - FB/2000V-WDC

PLANT FOR DECANTATION AND RECYCLING OF WASTE WATER AND FOR MUD DEHYDRATION Mod. FB/2000V-WD

Max. treatment capacity up to 500 l/min of waste water

WASTE WATER PUMP

Submersed pump.

Equipped with:

delivery pipe attachment;

rubber hosing;

connection cable for the start up.

AUTOMATIC FLOCCULANT STATION

Container

"Open air" container for mixing the flocculant, built in steel plate.

Equipped with:

attachment support for electric mixer;

steel section supports, complete with anchorages.

Helical electric mixer

Low speed mixer, designed for maximum utilization of separation properties of flocculant.

Power : kW 0.37

Speed : r.p.m. 70

Mixing shaft diameter : mm 30

Flocculant dosing pump

Nr. 1 piston motor-driven pump type FB 100 DL for batching with adequate delivery to the plant, for programming according to specific requirements.

Power : kW 0.37

Flow rate : l/h 0100

Maximum pressure : Bar 8

Equipped with:

gearbox body in aluminium;

head body in PVC;

ARNITE piston (diam. 70 mm);

flocculant delivery hose in wired rubber (max. pressure 10 bar, diam. 1/2");

bronze non return valve.

WASTE WATER DECANTATION UNIT

Static decanter

Decanter built in steel plate.

Diameter : mm 2.000

Cross section : mm 2.200 x 2.200

Overall height dimensions : mm 5.100

Equipped with:

flanged overflow channel for recovery of decanted water;

central pipeline for inlet of turbid water into distribution cone;

internal pressure-off cone to facilitate sedimentation of solids contained in the water;

distribution cone support beam built in section steel;

steel delivery pipe, including flanges and curves;

manual valve type FB 50 for regulating the waste water flow, fitted internally with anti-abrasive rubber sleeve;

steel collection pipe for treated water, including flanges and curves.

Internal decanter treatment

The decanter is internally lined with a corrosion proof, anti-abrasive and stick-proof lining. This lining protects the metal from incrustations and allows easy detaching of the sludge from the walls, in order to prevent system clogging.

AUTOMATIC MUD DISCHARGE

Equipped with:

manual valve FB 100 M;

pneumatic valve FB 100 P complete with rubber anti-abrasive sleeve;

solenoid exhaust valve for pneumatic cylinder pressure;

flange (diam. 100 mm) with rubber support for piping connection;

probe group for automatic pump operation and automatic decanter discharge

CLEAN WATER RESERVOIR

Steel container for decanted water (capacity 5,000 l) incorporated in the decanter structure

FILTERPRESS, Mod. FB/300-5 (Treatment capacity 0,011 m3 /cycle of dry mud)

Filterpress structure

Structure in electro-welded composite steel, specially processed to guarantee perfect machine operation.

Sliding filter plate supported by 2 wheels with PVC bushing, which slide on the head tie rods, and 2 contrast wheels.

Hydraulic power unit

Hydraulic power unit for feeding the cylinder. Hydraulic cylinder for opening and closing plates, equipped with sealing rings type Polipac.

Plates

Nr. 5 polypropylene plates sliding on PVC plates and dragged by chains.

Plate size : mm 300 x 300

Automatic system for dragging the plates and opening the chambers, with external support in hardened steel for shaking and discharging the mud panels.

Set of filter clothes and under clothes.

Drainage tubes from the two lower side angles of the plates for conveying filtered water to the collection channel.

Filtered water collection channels with flow regulator, complete with consenting probes which determine the end of the filtering process.

Shaker for the plates

Square-section shafts (mm 40x40), each one supported externally by nr. 1 support mounted on bearings.

Equipped with:

hardened cams for shaking inserted on the shaft;

nr. 1 central supports with PVC bushing;

reduction gear unit (power kW 0.18) with self-arresting motor;

adjustable disc for locking into the proper position

Anti splash hood

Anti-splash hood built in pressed plate and fitted onto the filter press structure.

Mud feeding system to the filterpress

Steel container for sludge collection, complete with probe fittings.

Equipped with:

probe group for functioning of the filterpress;

reinforced rubber hose (max. pressure 10 atm).

High pressure feeding membrane pump.

Features:

Max. flow rate : l/min 100

Max. pressure : atm 7

ELECTRIC PANEL BOARD

Electric panel board manufactured in painted steel plate with door locked by a main switch, according to current safety norms.

Equipped with:

remote controls for every use;

PLC

Colour of the machinery: GREY RAL 7044 + RED RAL 3000

VOLTAGE: 400 V - 50 Hz

FRACCAROLI & BALZAN WASTE WATER FILTRATION PLANT - ROUND MODEL - FB/2300V-WDC

PLANT FOR DECANTATION AND RECYCLING OF WASTE WATER AND FOR MUD DEHYDRATION Mod. FB/2300V-WD

Max. treatment capacity 750 l/min of waste water

WASTE WATER PUMP

Submersed pump.

Equipped with:

delivery pipe attachment;

rubber hosing;

connection cable for the start up.

AUTOMATIC FLOCCULANT STATION

Container

"Open air" container for mixing the flocculant, built in steel plate.

Equipped with:

attachment support for electric mixer;

steel section supports, complete with anchorages.

Helical electric mixer

Low speed mixer, designed for maximum utilization of separation properties of flocculant.

Power : kW 0.37

Speed : r.p.m. 70

Mixing shaft diameter : mm 30

Flocculant dosing pump

Nr. 1 piston motor-driven pump type FB 100 DL for batching with adequate delivery to the plant, for programming according to specific requirements.

Power : kW 0.37

Flow rate : l/h 0 100

Maximum pressure : Bar 8

Equipped with:

gearbox body in aluminium;

head body in PVC;

ARNITE piston (diam. 70 mm);

flocculant delivery hose in wired rubber (max. pressure 10 bar, diam. 1/2");

bronze non return valve.

WASTE WATER DECANTATION UNIT

Static decanter

Decanter built in steel plate.

Features

Diameter : mm 2.300

Overall height dimensions : mm 6.250

Equipped with:

flanged overflow channel for recovery of decanted water;

central pipeline for inlet of turbid water into distribution cone;

internal pressure-off cone to facilitate sedimentation of solids contained in the water;

distribution cone support beam built in section steel;

steel delivery pipe, including flanges and curves;

manual valve type FB 50 for regulating the waste water flow, fitted internally with anti-abrasive rubber sleeve;

steel collection pipe for treated water, including flanges and curves.

Internal decanter treatment

The decanter is internally lined with a corrosion proof, anti-abrasive and stick-proof lining. This lining protects the metal from incrustations and allows easy detaching of the sludge from the walls, in order to prevent system clogging.

AUTOMATIC MUD DISCHARGE

Equipped with:

manual valve FB 100 M;

pneumatic valve FB 100 P complete with rubber anti-abrasive sleeve;

solenoid exhaust valve for pneumatic cylinder pressure;

flange (diam. 100 mm) with rubber support for piping connection;

probe group for automatic pump operation and automatic decanter discharge

FILTERPRESS, Mod. FB/400-6 (Treatment capacity 0,020 m3 /cycle of dry mud)

Filterpress structure

Structure in electro-welded composite steel, specially processed to guarantee perfect machine operation.

Sliding filter plate supported by 2 wheels with PVC bushing, which slide on the head tie rods, and 2 contrast wheels.

Hydraulic power unit

Hydraulic power unit for feeding the cylinder. Hydraulic cylinder for opening and closing plates, equipped with sealing rings type Polipac.

Plates

Nr. 6 polypropylene plates sliding on PVC plates and dragged by chains.

Plate size mm 400 x 400

Automatic system for dragging the plates and opening the chambers, with external support in hardened steel for shaking and discharging the mud panels.

Set of filter clothes and under clothes.

Drainage tubes from the two lower side angles of the plates for conveying filtered water to the collection channel.

Filtered water collection channels with flow regulator, complete with consenting probes which determine the end of the filtering process.

Shaker for the plates

Square-section shafts (mm 40x40), each one supported externally by nr. 1 support mounted on bearings.

Equipped with:

hardened cams for shaking inserted on the shaft;

nr. 1 central supports with PVC bushing;

reduction gear unit (power kW 0.18) with self-arresting motor;

adjustable disc for locking into the proper position

Anti splash hood

Anti-splash hood built in pressed plate and fitted onto the filter press structure.

Mud feeding system to the filterpress

Steel container for sludge collection, complete with probe fittings.

Equipped with:

probe group for functioning of the filterpress;

reinforced rubber hose (max. pressure 10 atm).

High pressure feeding membrane pump.

Features:

Max. flow rate : l/min 100

Max. pressure : atm 7

ELECTRIC PANEL BOARD

Electric panel board manufactured in painted steel plate with door locked by a main switch, according to current safety norms.

Equipped with:

remote controls for every use;

PLC

Colour of the machinery: GREY RAL 7044 + RED RAL 3000

VOLTAGE: 400 V - 50 Hz

CMS Brembana Kosmos Jet Bridge Saw / Waterjet Combination CNC Machine

CMS Brembana Formax Jet Bridge Saw / WaterJET Combination CNC Machine

CMS Brembana Sprint Jet Bridge Saw / Waterjet Combination CNC Machine

5-axis saw jet machine

brembana sprint jet is a Numerically Controlled 5 interpolated-axis bridge saw equipped with tilting head and fixed table. It can carry out any type of machining, cutting (straight or shaped, vertical or inclined), 3D profiling and milling operations, on marble, granite, composite stone, and ceramic as well as stone blocks.

The machine is equipped with an abrasive waterjet cutting head that, working in combination with the diamond disk, enables automating natural and composite stone slab cutting operations when interfering cuts and internal angles are a factor. The AWJ head, integral with the main head, allows variable and small radius cutting, which would be impossible with just the diamond disk.

This machine can be customized to the customer's needs, it is the winning solution for every fabshop:

kitchen countertops

vanity tops

wall panels for interiors and exteriors

flooring

doorsteps, staircases and thresholds

street furniture

brembana sprint jet is also available with pallet change: The machine has an automatic system for pallet change that allows the operator to load the slab that needs to be cut outside the machine, while the machine is cutting another slab.

Advantages

UNRIVALLED MECHANICS

Open frame version, to install on concrete or carpentry shoulders guaranteeing stability and rigidity to accomplish the most difficult processing and to ensure long longevity.

EASY MAINTENANCE: 93% LESS COST FOR EXHAUSTED ABRASIVE REMOVAL

The catch tank with special anti-rust ceramic painting is designed to fit the new Evo4 chain dredge for exhausted abrasive removal even later after installation, with 93% less maintenance costs.

LIMITLESS TECHNOLOGY

5-axis cutting head with IKC technology. Effective head motion to carry out perfect miter cutting through the cut conicity and deflection control.

+33% PRODUCTIVITY WITHOUT MANUAL MOVEMENTS

Thanks to the vacuum manipulator, it is possible to automatically move the cut pieces to optimize the slab cutting and reduce waste processing.

Eye CMS - Consolle Digital System for CNC

Consolle eye-CMS

Simple, linear and elegant design with “full-screen” effect, entered horizontal lines are rendered brighter with LED.

Technical Data

no cooling fan, total protection from dust

front protection to direct and rear water jets with +/- 30°vertical tilting (Front IP65, Rear IP53)

multi-Touch screen with 10 contemporary touches

full HD Monitor LCD/LED 21.5” resolution 1920x1080, breadth of vision: 178° horizontal and 160° vertical (Zero pixel defect)

embedded Fast Ethernet Lan double port (1 Gigabit)

industrial-type power supply with wide range of use from 15V to 36V

intel processor, with professional multi-language Windows 7 Embedded

in compliance with all European and North American product standards

Advantages

stability and operating range

industrial standards (vibration, temperature, humidity, voltage uctuations, interference immunity)

total control over product quality and spareparts management

product continuity guaranteed and under control (7 years)

greater software application stability: no need for continuing upgrade stomatch uncontrolled hardware developments

system expandability for future developments (CPU, RAM, Hard Disk)

low power consumption

dual integrated Ethernet ports (avoiding the use of a USB converter which might lead to system instability)

minimum wiring

integrated watchdog (hardware circuit for cyclical monitoring of the vital system parts to prevent the risk of damage)

integrated software control of screen settings (brightness and contrast)

Sasso Revolution Edge Polisher

The perfect combination for amazing profiles

Thanks to the double spindle beam all limits of a traditional round edge polisher will be overcome. The most complicated toroidal edges can be produced and polished in a perfect and above all faster way.

MAX. THICKNESS 6 CM

6+5 HEADS ON ARM

2/4 BEVELS

Advantages

HOT DIP GALVANIZATION

Ensures the benches will last through time

MAXIMUM VERSATALITY

Thanks to the combination of 5 flat edge polishing heads and 6 torus heads, the machine can make all toroidal workings and flat edge polishing, including the Hollywood Bevel (2 cm bevel on flat edge) and round bevelling

MAXIMUM COMPLETENESS

The machine can be supplied with a multi-purpose spindle for special workings and up to 4 bevels

Manages complex profiles effectively and quickly

Maximum completeness

Sasso Seven Edge Polisher

A great edge polisher for maximum versatility

A wide machine frame to lodge additional spindles: this is the strenght of SEVEN. The most versatile edge polisher that opens up new working processes.

MAX. THICKNESS 10 CM

7/8 HEADS ON ARM

4/6 BEVELS

Advantages

HOT DIP GALVANIZATION

Ensures the benches will last through time

MAXIMUM PERFORMANCE

Thanks to the 4/6 bevels and 8 heads, the machine offers maximum performance in all kinds of work, be it flat edge or toroidal

VERSATILE AND COMPLETE

In addition to being particularly versatile, the machine can be supplied with multi-purpose spindles for special workings

Maximum results on all kinds of workings

Customisable and versatile, for special workings

Sasso Evolution Edge Polisher

Powerful from every angle

Optimised layout of the spindles for an edge polisher that accelerates profiling and polishing. This reduces idle times and boosts production.

MAX. THICKNESS 10 CM

8 HEADS ON ARM

4 BEVELS

Advantages

HOT DIP GALVANIZATION

Ensures the benches will last through time

MAXIMUM OF THICKNESS

The 4 pre-cutting bevels and the 8 torus area heads make it easier to work on thicker profiles

VERSATILE AND COMPLETE

In addition to being particularly versatile, the machine can be supplied with multi-purpose spindles for special workings

Perfect to make it easier to work on thicker slabs

Thanks to its 4 pre-cutting bevels and 8 torus area heads, it can work slabs up to 10 cm thick.

Optimised layout of the spindles for an edge polisher that accelerates profiling and polishing

Perfect for reduces idle times and boosts production.

Sasso Flying Bull edge Polisher

Top performance at an affordable price

For high performance at a reasonable cost, Sasso created FLYING BULL. The perfect machine to polish flat and round edges, offering several options to complete the work.

MAX. THICKNESS 10 CM

6 HEADS ON ARM

2+2 OPT BEVELS

Advantages

HOT DIP GALVANIZATION

Ensures the benches will last through time

ALL IN LESS THAN 5 M

Flying Bull can be configured with multi-purpose spindles for special workings, in addition to normal edge polishing.

VERSATILE AND HIGH PERFORMANCE

Possibility to work on very large and very thick pieces

The perfect machine to polish flat and round edge

Can be configured for special workings